Avoid costly breakdowns and maximize the lifespan of your machinery with expert alignment services. At Innovative Measurement Solutions, we ensure your equipment operates at peak performance by delivering precise, reliable alignment tailored to your specific needs.

Improper alignment can silently undermine your operations, leading to frequent breakdowns, reduced efficiency, and premature wear on critical equipment. These issues don’t just disrupt workflows—they escalate costs, compromise safety, and shorten your machinery’s lifespan. At Innovative Measurement Solutions, we tackle these challenges head-on with our precision alignment services. Here’s how we help:

By identifying and correcting misalignments early, we keep your machinery running smoothly, avoiding unplanned outages and expensive emergency repairs.

Properly aligned equipment operates at peak performance, reducing energy consumption and improving overall productivity.

Our precise alignment adjustments minimize wear and tear, protecting your investment and maximizing the lifespan of your machinery.

Keep machinery running smoothly and efficiently.

Prevent interruptions with accurate alignment.

Reduce wear and tear, ensuring long-term reliability.

We combine expert knowledge with cutting-edge technology to deliver results:

Conduct a detailed evaluation of your equipment’s current alignment.

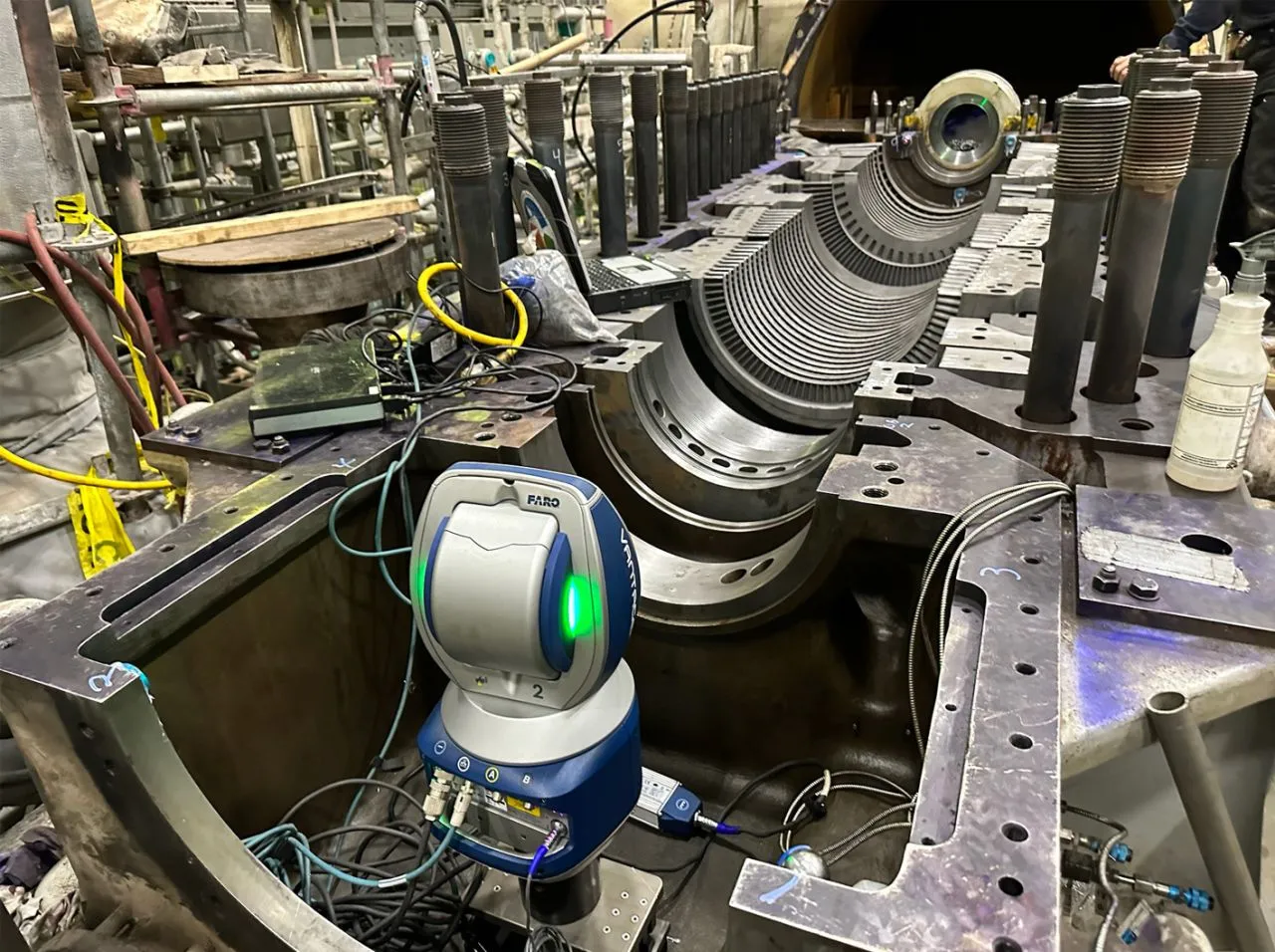

Use laser trackers and precision tools to capture accurate alignment measurements.

Correct any deviations to achieve optimal alignment.

Perform a post-alignment analysis to confirm accuracy and provide a detailed report.

Successfully aligning equipment across industries since 2010.

Our CMSC-certified team ensures accuracy and quality at every step.

State-of-the-art laser trackers and alignment systems deliver unparalleled precision.

Tailored services designed to meet the unique needs of your operation.

Equipment alignment isn’t a one-time task. Regular checks help identify misalignments caused by wear and tear, vibrations, or environmental factors. Proactive maintenance prevents small issues from escalating into costly breakdowns, ensuring your machinery operates efficiently and reliably over time.

Traditional alignment methods often lack the precision needed for modern machinery. Advanced tools such as laser trackers and 3D scanning systems provide unparalleled accuracy, ensuring perfectly aligned components. These tools reduce the margin of error and improve operational consistency.

Alignment isn’t just about using the right tools—it’s about interpreting data and applying it effectively. Experienced professionals bring the expertise needed to analyze measurements, identify potential challenges, and execute precise adjustments. Partnering with experts ensures your equipment performs at its best and minimizes costly downtime.

Unusual vibrations, uneven wear on parts, inconsistent product quality, or increased energy consumption are common signs your equipment needs service. If you’ve noticed any of these or if your equipment isn’t performing as efficiently as it used to, it’s worth scheduling an alignment check. Even if you’re unsure, a quick assessment can save you from potential downtime later. Schedule a service appointment here.

It really depends on the complexity of the project and the size of your equipment, but we prioritize efficiency without compromising accuracy. For many projects, the process can be completed in a day or two, including assessment, adjustments, and verification. For larger or more intricate setups, we’ll provide you with a clear timeline during the consultation. Book a consultation here.

Absolutely! We understand how important it is to keep operations running smoothly. In many cases, we can work alongside your team to minimize disruptions. Whether it’s scheduling services during low-activity periods or coordinating around your workflow, we’ll tailor our approach to fit your needs.

Our team is CMSC-certified, which means we adhere to the highest standards in metrology and alignment services. We also use state-of-the-art tools like laser trackers and precision measurement devices to ensure every adjustment meets industry benchmarks. If you have specific standards or requirements for your project, we’re happy to align with those as well.

Yes, we do! We offer ongoing support to ensure your equipment stays in peak condition. This can include periodic rechecks, maintenance plans, or even on-call services for troubleshooting. Our goal is to help you maintain long-term reliability and prevent misalignments from creeping back in.