Guarantee the accuracy and performance of your tooling and fixtures with our tooling and fixture certification services. At Innovative Measurement Solutions, we provide comprehensive certification processes that verify your equipment meets industry standards, ensuring quality and precision in every project.

Uncertified or misaligned tooling and fixtures can compromise accuracy, leading to production delays, costly rework, and non-compliance with industry standards. Over time, wear and improper handling exacerbate these issues, risking product quality and operational efficiency. Our tooling and fixture certification services address these challenges by:

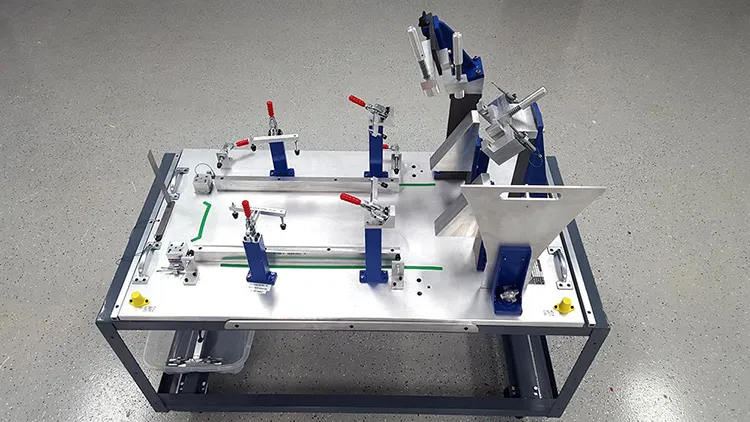

Advanced measurement tools evaluate alignment and performance with precision.

Regular certifications prevent misalignments and unexpected failures.

Comprehensive reports ensure compliance with industry and regulatory standards.

Ongoing support and periodic recertification maintain consistent quality and performance.

Verify that all tooling and fixtures meet precise specifications.

Reduce downtime by ensuring equipment operates reliably.

Meet industry and regulatory standards with confidence.

Evaluate tooling and fixtures to identify calibration and certification requirements.

Use advanced measurement tools to verify alignment, accuracy, and functionality.

Provide detailed reports and certifications that meet industry standards.

Offer periodic recertifications to maintain long-term reliability.

CMSC-certified experts with extensive experience in tooling and fixture certification.

Equipped with cutting-edge laser scanners and CMM technology for precise assessments.

Tailored certification programs designed to meet your unique project requirements.

Plan routine certifications to catch misalignments early, ensuring consistent quality and avoiding costly rework or downtime.

Rely on precise equipment like laser trackers and CMMs for accurate and reliable certifications that meet industry standards.

Work with experienced experts to handle complex certification processes, interpret results, and ensure compliance with regulatory requirements.

Failing to certify tooling and fixtures regularly can lead to several issues, including inaccurate measurements, production delays, and increased costs due to rework or scrap. Over time, misaligned tools can compromise product quality and even result in non-compliance with industry standards, potentially damaging your reputation and risking penalties.

Yes, we specialize in certifying both standard and highly customized tooling and fixtures. Our tailored certification programs are designed to accommodate unique specifications, ensuring even the most complex tools meet your precise requirements.

We follow recognized industry standards such as ISO 9001, ASME, and other relevant guidelines specific to your industry. Our certifications ensure compliance with both regulatory requirements and customer specifications, giving you confidence in your tooling’s reliability.

We work closely with your team to schedule on-site certifications during non-peak hours or planned maintenance periods to minimize downtime. Our efficient processes and advanced tools allow us to complete certifications quickly without compromising accuracy or quality.

Yes, we provide training and maintenance guidance to help your team properly care for and handle certified tools. This includes best practices for storage, usage, and regular inspections to prolong the life of your equipment and maintain its accuracy between certifications.