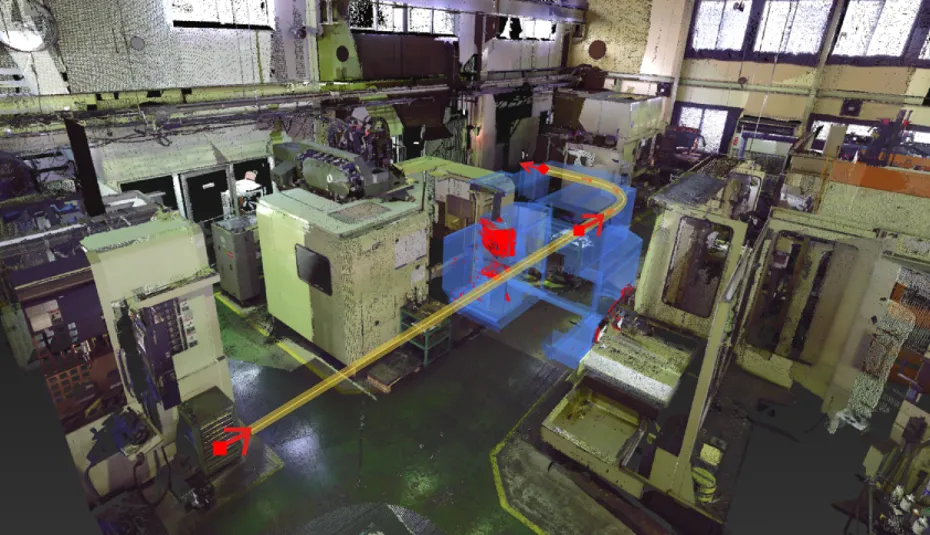

To achieve seamless integration during your outage, it is essential to conduct load path interference checks. These checks help identify potential conflicts where equipment travel paths may be obstructed with existing structures. By prioritizing these checks, you can optimize efficiency and have fewer disruptions during your outage.

Achieving seamless component alignment is essential for efficient assembly, yet misaligned parts can result in costly rework, production delays, compromised product quality, and inefficient processes. These issues not only disrupt schedules and increase expenses but also risk the integrity and functionality of the final product, making precise alignment critical for success. We solve these challenges with our fit-up prediction services:

Advanced laser scanning and metrology tools allow us to identify alignment problems before they cause delays or added costs.

Our CMSC-certified experts deliver tailored, actionable insights to ensure every component aligns perfectly, reducing guesswork.

By resolving fit-up issues early, we help you avoid disruptions, speed up assembly, and minimize rework.

Accurate predictions ensure flawless alignment, improving both product integrity and operational efficiency.

Identify and resolve alignment challenges early to prevent rework and delays.

Ensure components align seamlessly for smooth and efficient assembly.

Enhance project efficiency with accurate, actionable insights.

Using advanced laser scanning and metrology tools, we capture precise measurements of your components.

Our CMSC-certified experts identify potential alignment issues and anticipate challenges before they arise.

We provide a detailed report with actionable solutions to optimize your assembly process.

Our team works closely with you to ensure seamless integration and flawless fit-up.

Here’s why we’re the trusted choice for dimensional control:

Over 10 years of experience solving complex fit-up challenges across multiple industries.

We utilize state-of-the-art tools for reliable and precise predictions.

Every project is tailored to meet your unique requirements, ensuring the best results.

The cost really depends on the complexity of your project, the number of components involved, and the level of detail required. We tailor our services to meet your specific needs, so you’re only paying for what’s necessary to achieve flawless alignment. If you’d like, we can set up a consultation to go over your project and provide a customized quote. Get a quote here!

Absolutely! We specialize in tackling complex and custom-built assemblies. Whether you’re working on a one-of-a-kind prototype or a highly detailed project, our tools and expertise can adapt to your requirements. Every project is unique, and we thrive on finding solutions for even the most challenging fit-up scenarios. Feel free to reach out to us for more specific information.

We’ve worked extensively with industries like aerospace, manufacturing, automotive, and shipbuilding. For instance, in aerospace, our fit-up predictions helped a client avoid weeks of delays and significant rework costs by addressing alignment issues before assembly began. If you’re curious about results in your industry, we’d be happy to share more examples during a consultation. Schedule a consultation here.

While our predictions are designed to catch potential issues before they occur, we understand that challenges can still arise. If alignment issues surface during production, we can step in with on-site support to analyze the situation and recommend corrective actions. Our goal is to keep your project on track, no matter what stage you’re in.

The cost really depends on the complexity of your project, the number of components involved, and the level of detail required. We tailor our services to meet your specific needs, so you’re only paying for what’s necessary to achieve flawless alignment. If you’d like, we can set up a consultation to go over your project and provide a customized quote. Get a quote here!

Absolutely! We specialize in tackling complex and custom-built assemblies. Whether you’re working on a one-of-a-kind prototype or a highly detailed project, our tools and expertise can adapt to your requirements. Every project is unique, and we thrive on finding solutions for even the most challenging fit-up scenarios. Feel free to reach out to us for more specific information.

We’ve worked extensively with industries like aerospace, manufacturing, automotive, and shipbuilding. For instance, in aerospace, our fit-up predictions helped a client avoid weeks of delays and significant rework costs by addressing alignment issues before assembly began. If you’re curious about results in your industry, we’d be happy to share more examples during a consultation. Schedule a consultation here.

While our predictions are designed to catch potential issues before they occur, we understand that challenges can still arise. If alignment issues surface during production, we can step in with on-site support to analyze the situation and recommend corrective actions. Our goal is to keep your project on track, no matter what stage you’re in.

We take data security very seriously. All measurements and project details are stored securely, and only authorized team members have access to them. If needed, we’re happy to sign NDAs and adhere to any additional security protocols you require to ensure your intellectual property is fully protected.